OASI Production Intelligence - Where creation meets precision.

OASI Production Intelligence transforms the way collections are created by unifying design and production into a single intelligent workflow.

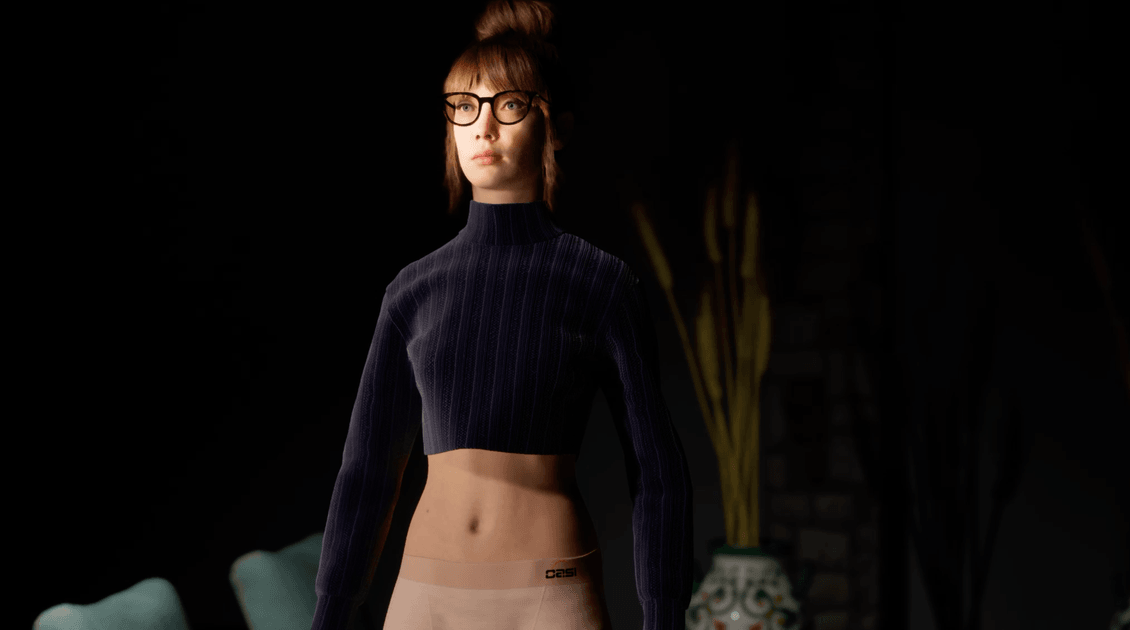

Designers upload their 2D or 3D pattern files to the OASI Dashboard, where they instantly become hyper-realistic digital garments rendered on real human models scanned or selected by the brand.

For the first time, creative and technical teams can visualize, test, refine, and approve garments before a single physical sample exists.

The result?

Dramatically faster prototyping. Lower costs. Near-zero material waste.

Why it matters

- Cuts prototyping time and costs with true-to-life digital samples

- Gives designers complete creative freedom without material limits

- Reduces waste and emissions by eliminating unnecessary prototypes

- Aligns design, development, and production teams in one shared workspace

- Improves production accuracy through validated digital data

_____________________________________________________________________________________________________________________________________

Two ways to experience Production Intelligence

Production Intelligence - Catalog Model

A plug-and-play digital prototyping solution using OASI’s curated 3D model library.

Designers upload pattern files, visualize garments on realistic models, test fit and drape, and approve samples — all digitally.

Ideal for fast onboarding and immediate workflow transformation.

_____________________________________________________________________________________________________________________________________

Production Intelligence - Custom Scan

The advanced version with full scanning integration.

Brands can digitize their own models to create accurate human twins, achieving unmatched realism and production precision.

Perfect for luxury and high-end brands that require custom digital bodies for advanced fitting and highly accurate production workflows.